Galvanized steel is one of the most common steel type due to its long durability, the toughness and ductility of steel, and the corrosion protection provided by the zinc-iron coating. The zinc acts as a barrier to corrosive elements, protecting the base metal, and then its coating results in a long-lasting and strong steel material. Galvanized steel provides all of the benefits that steel construction currently has, plus the extra bonus of galvanization protection.

Because of its adaptability, it can be utilized in a wide range of projects and sectors of construction.

When making anything that will last for decades, everyone wants to utilize the best materials available. As a result, more individuals are opting for galvanized steel in construction. Steel is the finest galvanized metal for building for a variety of reasons.

6 Top Reasons for Using Galvanized Steel For Your Construction

● Strong and Reliable: Galvanized steel has the same bend, impact, proof, and tensile strength as normal structural steel making it even more strong and reliable. Galvanized steel does not rust, allowing it to be utilized in the manufacturing of PEB and solar.

● Less Maintenance: Galvanized steel applications like duct work, ladders, fencing and more require little to no maintenance as the hot dip galvanizing process ensures the steel will never shrink or crack because it is metallurgically bonded to the steel it protects. It also offers resistance to abrasion and water.

● Complete Protection: Zinc coating from hot dip galvanizing process is reasonably smooth and gives off protections as it is free from imperfections such as flux, ash, dross inclusions, black spots, and rust strains which makes it applicable for panels and household appliances.

● Saves Labour Time: Because of a protective layer of zinc in the hot dipped galvanizing process, other coatings are not required to be sprayed or painted on the steel which eventually saves labor time and can be utilized as a roof. The zinc acts as a protective buffer between the steel and any moisture or oxygen which makes it damage resistance and it just has to be cleaned a couple times a year.

● Multiple Uses: Galvanized steel is one of the most environmentally beneficial building materials on the globe since it is almost always recycled steel and can be reused in beams and column structures.

● Longevity: Galvanized coatings on ordinary structural parts have a life expectancy of more than 50 years in most rural areas, and 20 to 25 years or more in harsh urban and coastal situations, making it a major benefit for pre-engineered buildings.

Applications of Galvanized Steel in Construction

Some of the applications and reasons for using galvanized steel for construction are:

1. Pre-engineered Building: Galvanized steel is commonly used in the construction of buildings, bridges, and other structures. The corrosion resistance of the zinc coating helps to protect the structural steel from rust and corrosion, extending the life of the structure.

2. Roofing and Cladding: Galvanized steel sheet is often used as roofing and cladding material due to its durability, strength, and low maintenance requirements. The zinc coating helps to protect the steel from weathering, ensuring a longer lifespan for the structure.

3. Fencing: Galvanized steel is commonly used for fencing, such as chain link and welded wire fencing, because it is strong, durable, and resistant to rust and corrosion. This makes it ideal for use in harsh outdoor environments.

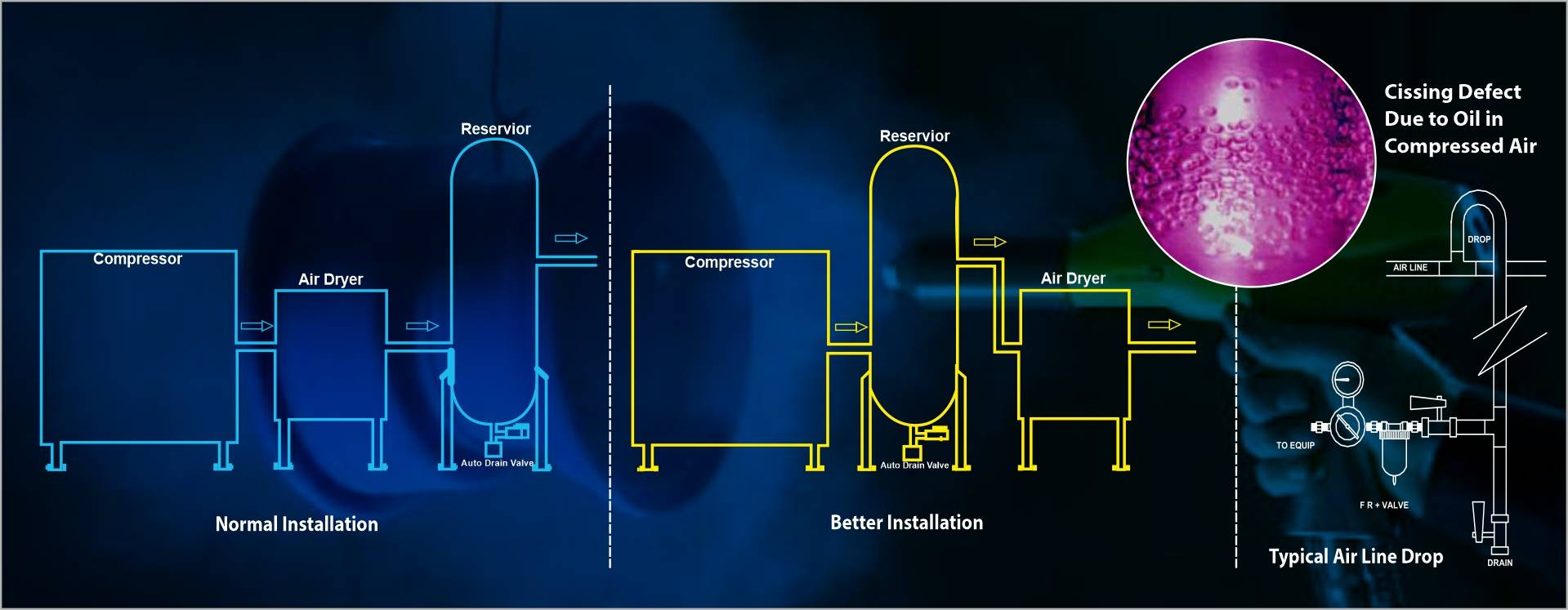

4. Heating, Ventilation and Air Conditioning: Galvanized steel is often used in the construction of HVAC (heating, ventilation, and air conditioning) systems due to its strength, durability, and resistance to corrosion. It is commonly used for ductwork, exhaust systems, and other components.

5. Electrical Transmission Towers: Galvanized steel is commonly used in the construction of electrical transmission towers like monopoles and lattice towers due to its strength, durability, and resistance to corrosion. The zinc coating helps to protect the steel from weathering and corrosion, ensuring a longer lifespan for the structure.

Role of Ecafez in Galvanized Steel

Galvano is Tata Steel's ecologically and economically superior galvanized plain (GP) steel that not only satisfies the need for a sophisticated product for modern steel applications, with its zero-spangle surface, but it does so in full compliance with RoHS standards.

Galvano has literally galvanized the coated steel market as it gets showcased in everyday life from the washing machine component and dish antennas to the refrigerator, from electrical panels to general engineering parts and bus bodies. It spans innumerable uses, always delivering quality, improving customer satisfaction and always paying homage to nature.

It addressed the unfulfilled need of quality-conscious customers for an authentic product that delivered consistent quality. In a clear departure from the run of the mini-spangled and crushed spangle products, Galvano was truly zero-spangle. Its unique chemistry ensures zero-spangles on the surface for superior and unmatched surface finish and mechanical properties that were a source of customer delight. In becoming a lead-free and completely green product Galvano has raised the bar for galvanized steel.

Features of Tata Galvano Steel

Galvano tata steel has numerous features, such as -

● Superior surface finish

● Enhance flatness

● Uniform mechanical properties

● Packaging and source authenticity

● Enhanced drawability

● Tighter tolerances

● Corrosion resistance

● Chemical free coating and eco friendly

How Ecafez can help

As a business owner or SME owner, Ecafez contributes to economic progress. Ecafez brands offer a diverse selection of world-class solutions in goods and services adapted to unique needs. Our team is available to users for round-the-clock support to guide and advise them.