In the vast realm of steel manufacturing, there are numerous processes aimed at enhancing the quality and appearance of steel products. One such transformative process is hot rolled dry skin pass, which involves treating hot rolled steel to achieve a smoother and cleaner surface. From automotive components and architectural structures to household goods and general engineering applications, hot rolled dry skin pass steel finds its place across diverse industries. By undergoing the meticulous skin pass-rolling process, the steel undergoes a remarkable transformation, rendering it highly desirable for an array of applications.

Understanding Hot Rolled Dry Skin Pass Steel:

Hot rolled dry skin pass steel refers to a type of steel that undergoes a crucial post-processing treatment known as skin pass rolling. Skin pass rolling is performed on hot-rolled steel to improve its surface finish and eliminate any scale, dirt, or imperfections. This process entails subjecting the steel to a gentle mechanical abrasion or brushing, resulting in a noticeably smoother and cleaner surface. Importantly, this treatment does not involve the application of any coating or chemicals, thus preserving the steel's original composition and properties.

The Skin Pass Rolling Process: Refining Steel to Perfection

The skin pass-rolling process plays a vital role in enhancing the surface quality of hot-rolled steel. After the initial hot rolling process, where the steel is heated and shaped, the surface may develop an oxide layer or scale due to exposure to high temperatures. Skin pass rolling diligently addresses this concern by meticulously removing the scale and imparting a uniform matte or smooth finish to the steel.

STEP-1

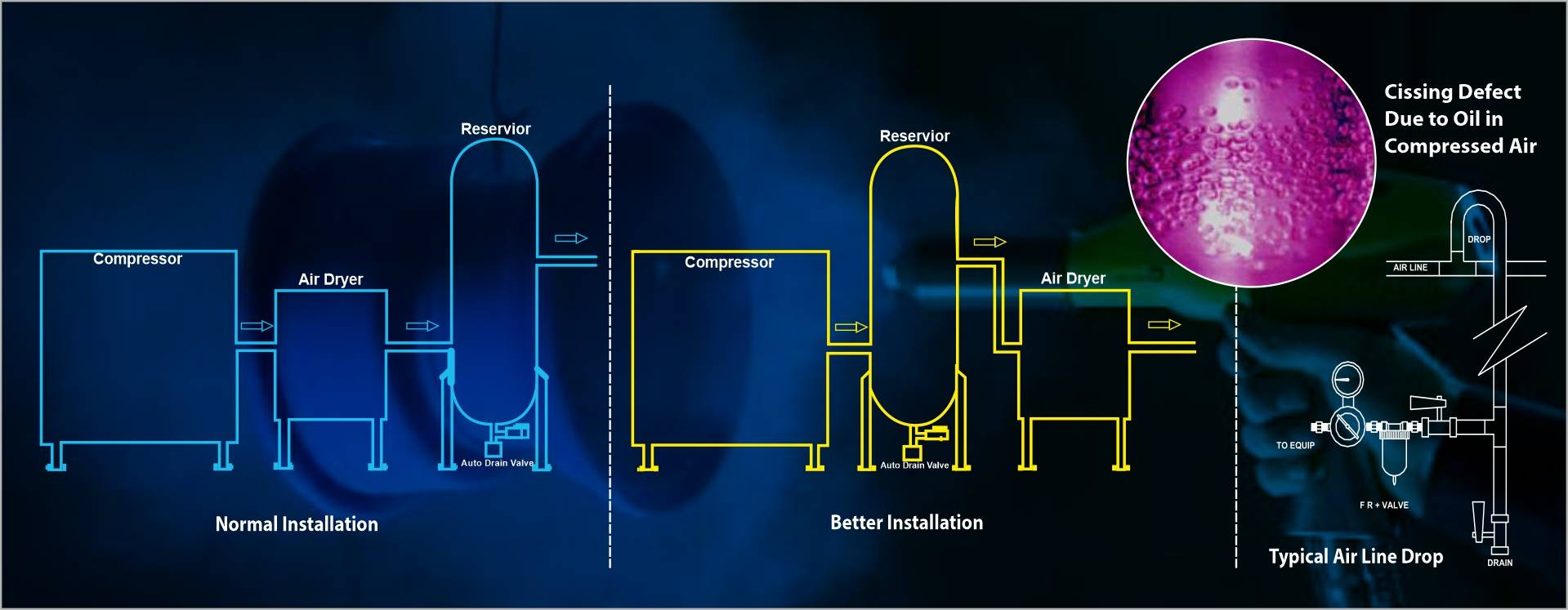

The process begins with carefully feeding the hot rolled steel into a series of specialized rolls. These rolls are precisely engineered to exert controlled pressure and traction on the steel, effectively reducing its thickness while maintaining structural integrity. The rolls are meticulously calibrated to ensure optimal pressure distribution, preventing any deformations or distortions while effectively removing imperfections, scale, and irregularities from the surface.

STEP-2

To enhance the efficacy of the skin pass-rolling process, advanced lubrication techniques are employed. Lubricants, specifically formulated for this purpose, are carefully applied to the rolls. This lubrication not only reduces friction but also ensures a smooth passage of the steel through the rolls, further refining the surface quality. The strategic use of lubricants minimizes the risk of surface damage or scratching, contributing to the overall impeccable finish of the hot rolled dry skin pass steel.

STEP-3

As the hot rolled steel progresses through the rolls, the combination of pressure, traction, and lubrication works harmoniously to refine the surface, gradually transforming it into a pristine canvas. The careful application of force and controlled reduction in thickness result in a remarkably uniform and consistent matte or smooth finish. This level of precision is essential to achieve the desired surface quality, ensuring that the hot rolled dry skin pass steel exhibits exceptional visual appeal and a texture that is free from imperfections.

Advantages of Hot Rolled Dry Skin Pass Steel:

Hot rolled dry skin pass steel offers a multitude of advantages that make it a preferred choice in various industries:

Enhanced Surface Quality:

The skin pass-rolling process eliminates scale, dirt, and imperfections, resulting in a significantly smoother and cleaner surface. This enhanced surface quality not only contributes to improved aesthetics but also facilitates better paint adhesion for subsequent coatings.

Superior Paint Adhesion:

The exceptionally smooth surface of hot rolled dry skin pass steel serves as an ideal substrate for paints and coatings. It ensures superior adhesion, allowing for long-lasting and visually appealing finishes that withstand the test of time.

Enhanced Corrosion Resistance:

By removing the scale during the skin pass rolling process, the steel's resistance to corrosion is notably improved. This quality makes hot rolled dry skin pass steel particularly suitable for applications where durability and protection against the elements are paramount.

Applications of Hot Rolled Dry Skin Pass Steel:

Automotive Industry: Hot rolled dry skin pass steel finds extensive use in the automotive industry, where it is employed in the manufacturing of body panels, doors, hoods, and various structural components. The improved surface quality, combined with superior paint adhesion, ensures enhanced aesthetic appeal, durability, and longevity of automotive parts.

Construction and Architecture: The construction and architecture sectors extensively rely on hot rolled dry skin pass steel for applications such as roofing, cladding, and structural elements. Its smooth surface, coupled with superior paint adhesion and corrosion resistance, guarantees long-lasting performance and visual allure in buildings and structures.

Appliances and Household Goods: Hot rolled dry skin pass steel is widely utilized in the production of kitchen appliances, home furniture, and fixtures. Its clean and smooth surface enhances the overall appearance while providing excellent resistance against scratches and wear, ensuring the longevity of these everyday essentials.

General Engineering: Hot rolled dry skin pass steel finds applications in various engineering components and equipment. Its improved surface finish, combined with better formability and superior paint adhesion, makes it a preferred choice for machinery, industrial components, and other engineering applications.

Tata DigEca: Pioneers in Hot Rolled Steel Products

When it comes to hot-rolled steel products, Tata DigEca stands out as a renowned and reliable provider. With a steadfast commitment to innovation and customer satisfaction, Tata DigEca delivers exceptional hot-rolled steel solutions, including hot-rolled dry skin pass steel. Renowned for its superior surface quality, unwavering reliability, and outstanding performance, Tata DigEca's hot-rolled steel products are trusted by industries worldwide.

Conclusion:

Hot rolled dry skin pass steel, achieved through the meticulous skin pass rolling process, offers significant advantages in terms of surface quality and performance. Its enhanced surface finish, superior paint adhesion, and improved corrosion resistance make it an ideal choice for a wide array of applications in the automotive, construction, appliances, and general engineering industries. Tata DigEca, with its unwavering expertise and steadfast commitment to excellence, remains an undisputed leader in providing high-quality hot-rolled steel products. Consider hot rolled dry skin pass steel from Tata DigEca for your next project and experience the unparalleled benefits of its superior surface quality and exceptional longevity.